Turkish chips production and production line 400 kg production capacity - automatic chips production lines

Available product shapes

video

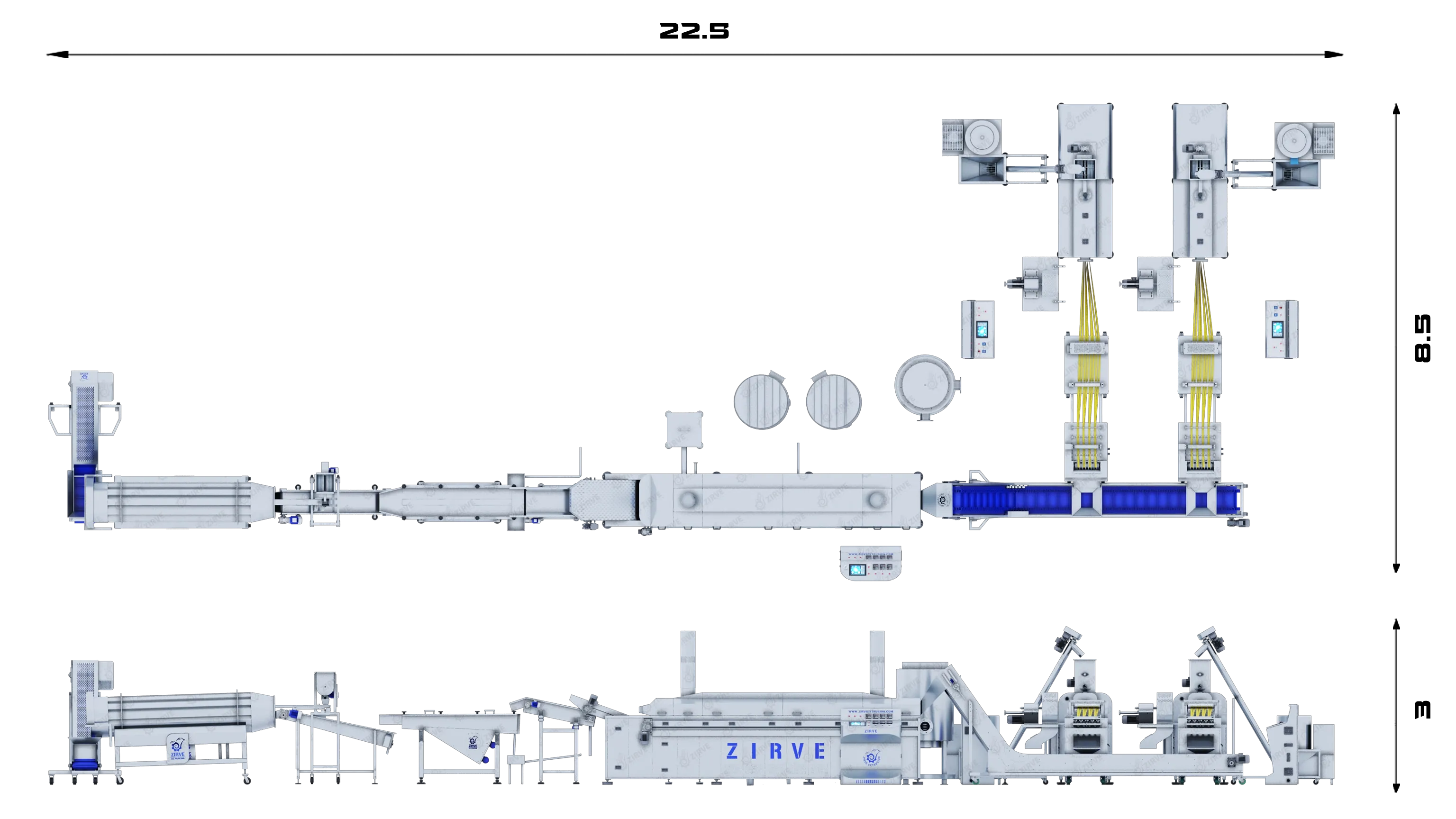

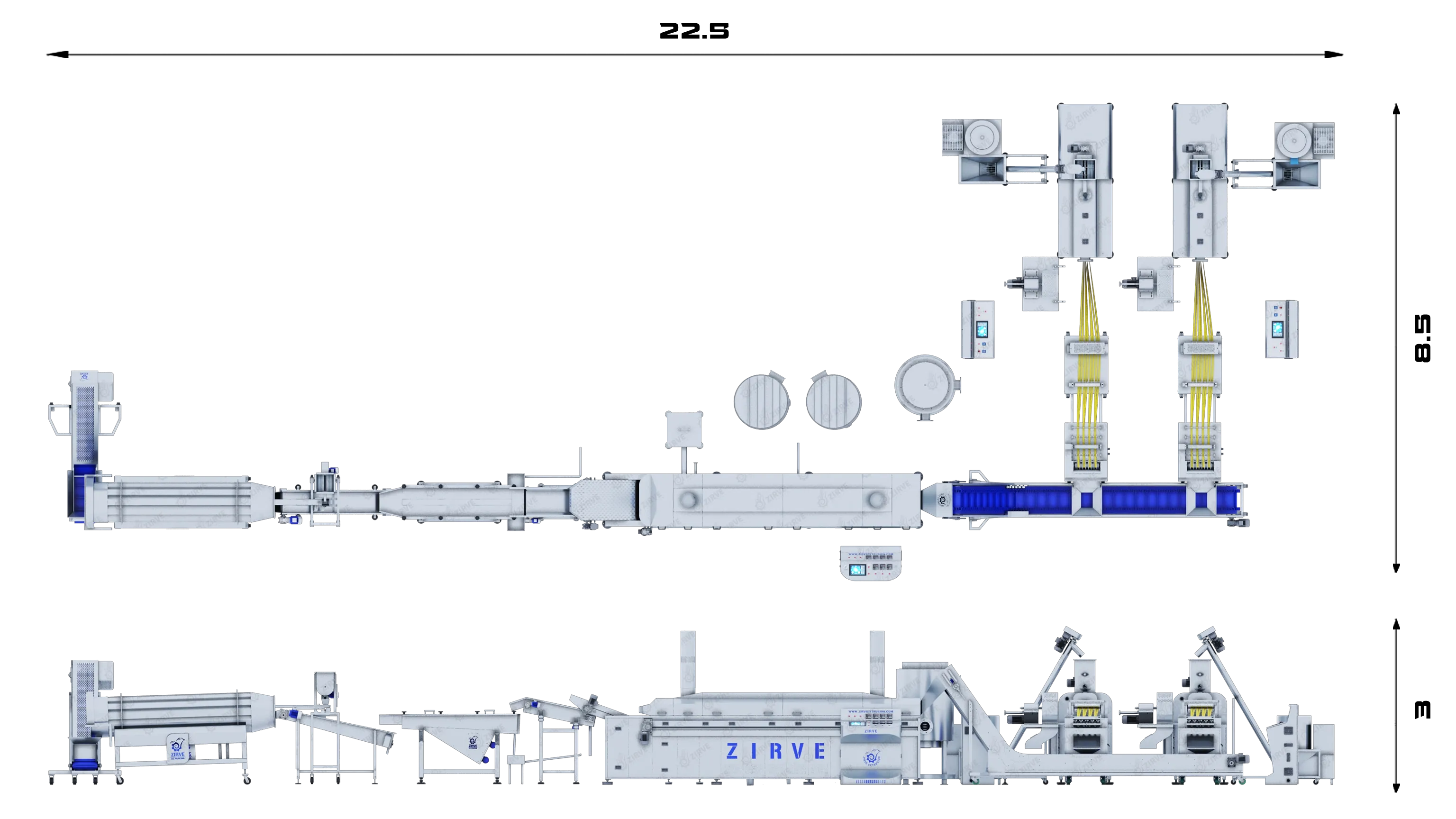

Specifications

6 People

124 Kw

153 Sqm

400 Kg

PRODUCTION LINE OVERVIEW

LINE PRODUCTION UNITS OVERVIEW

Dimensions