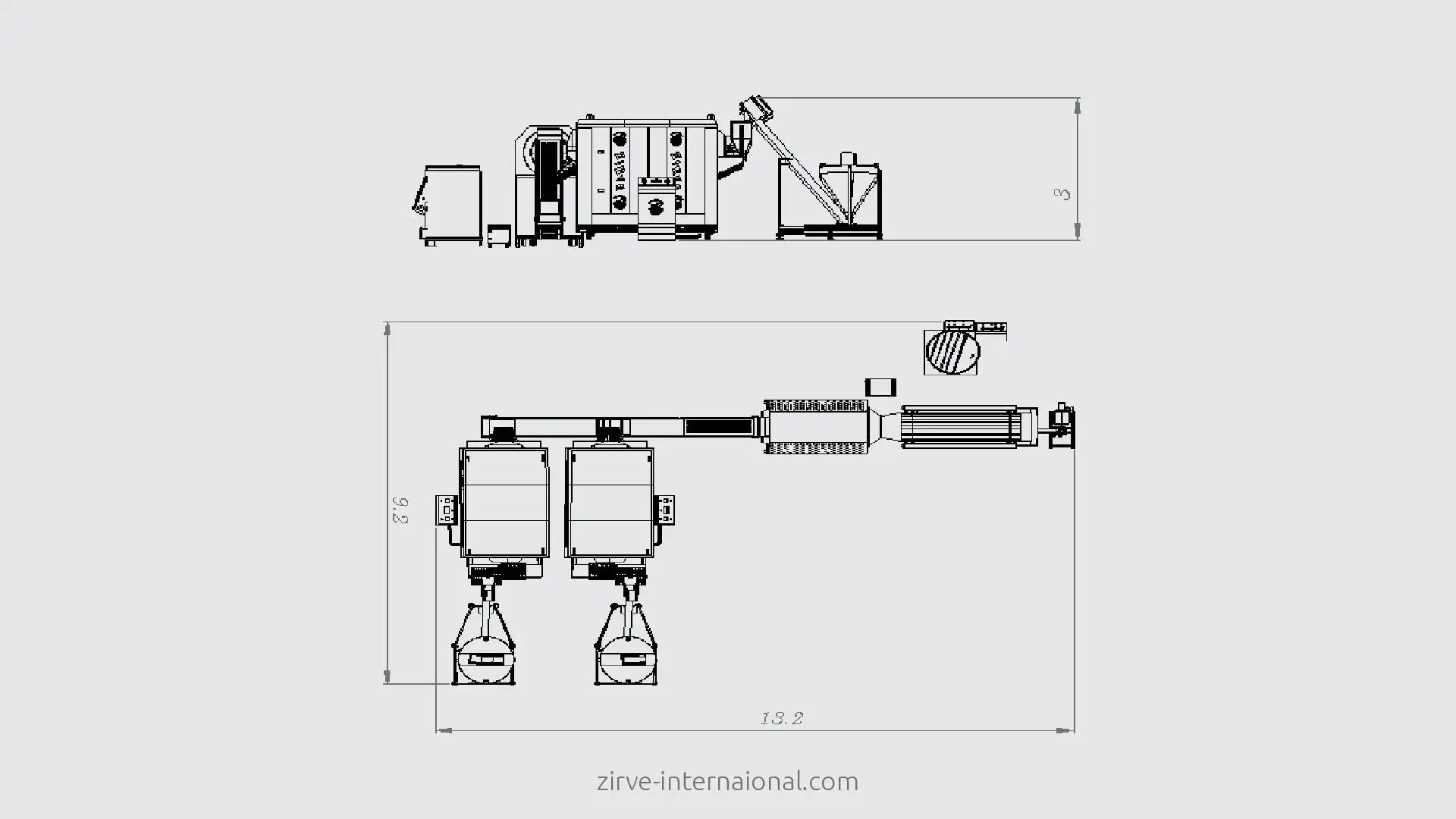

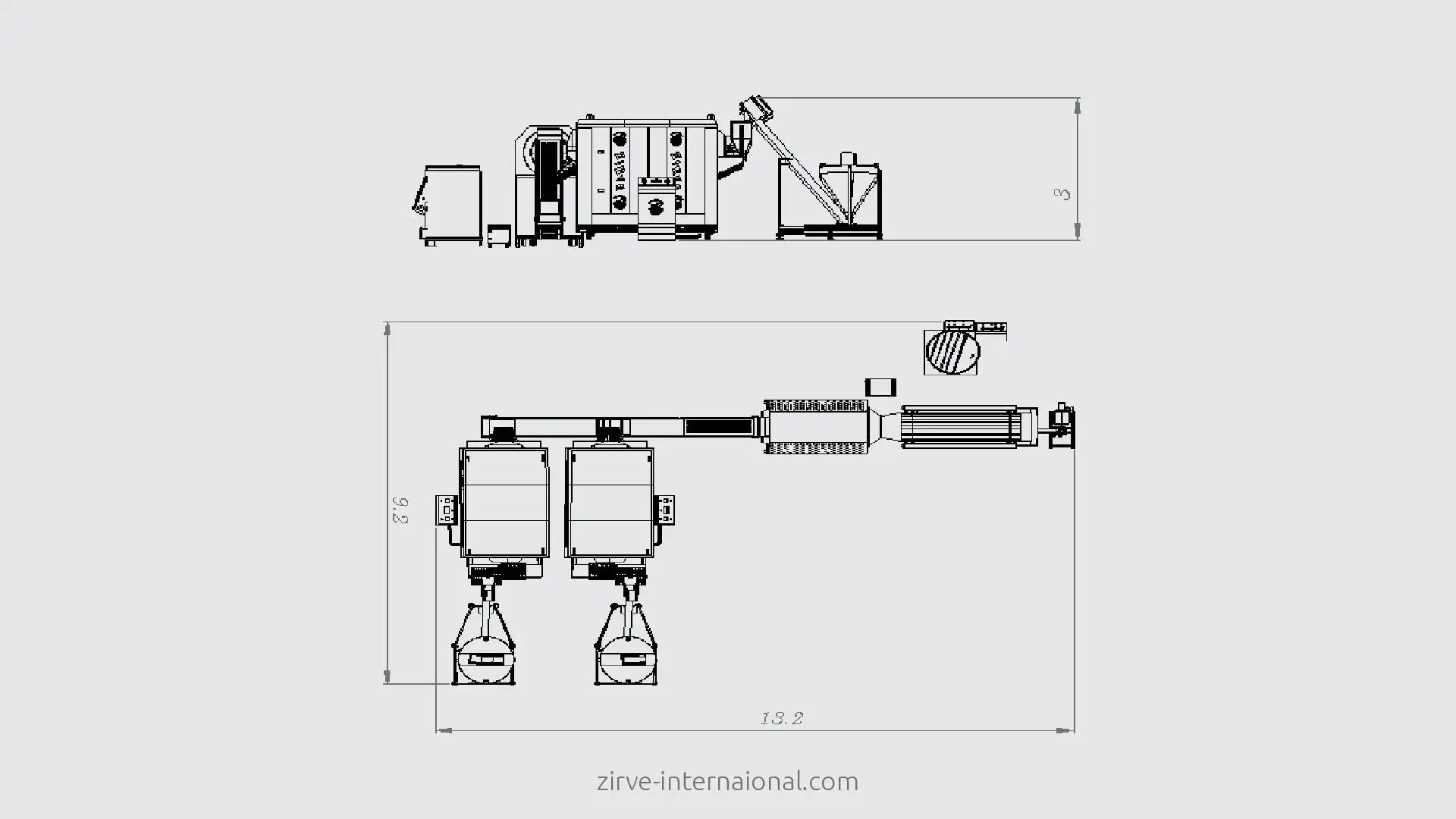

<p><strong>The process of making popcorn and blowing corn grains is done by hot air without oil </strong></p><p><strong>Exactly matching the American model CRETORS</strong></p><p><strong>Manufactured and equipped for continuous work 24/7</strong></p><p><strong>Length / 220 / cm, width / 100 / cm, height / 180 / cm.</strong></p><p><strong>Production capacity / 120 / to / 130/kg per hour,</strong></p><p><strong>The machine operates with open circuit system (continuous flow)</strong></p><p><strong>Equipped with Belgian screwdrivers, a precision control and calibration industry</strong></p><p><strong>Powered By LPG gas (on request)</strong></p><p><strong>It is equipped with Burners Italian ECOFLAM brand</strong></p><p><strong>Equipped with a / 12 / cm insulation layer of glass fiber over the whole structure area</strong></p><p><strong>Made entirely of / stainless steel 304 /.</strong></p><p><strong>Equipped with a main engine capacity of / 4 / hp / 3 / kW Turkish industry.</strong></p><p><strong>Equipped with a rotary engine capacity of 1 hp Turkish industry GAMAK brand with a Gearbox from the Italian company VARVEL.</strong></p><p><strong>Total capacity / 3 / kW / 380 / V / 50 / Hz</strong></p><p><strong>Equipped with a Stainless steel control panel, all control, protection and protection parts are supplied by SCHNEIDER brand France.</strong></p><p><strong>Features a touch control screen with Two languages English, Persian.</strong></p><p><strong>Equipped with / 2 / temperature clock, a Korean brand of AUTONICS precise tuning and calibration</strong></p><p><strong>Equipped with / 2 / air temperature sensors Italian industry</strong></p>