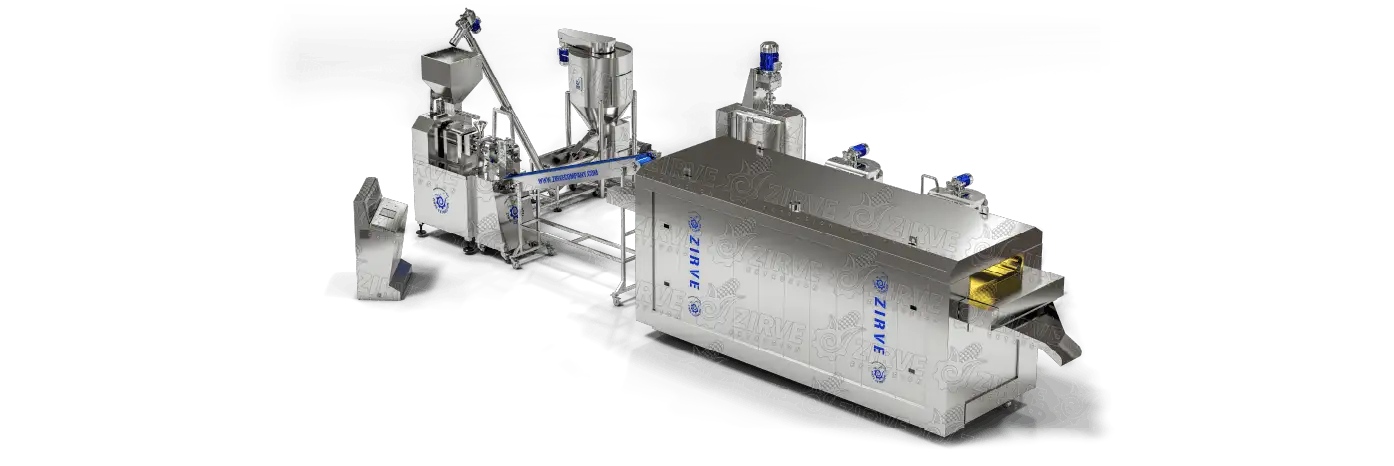

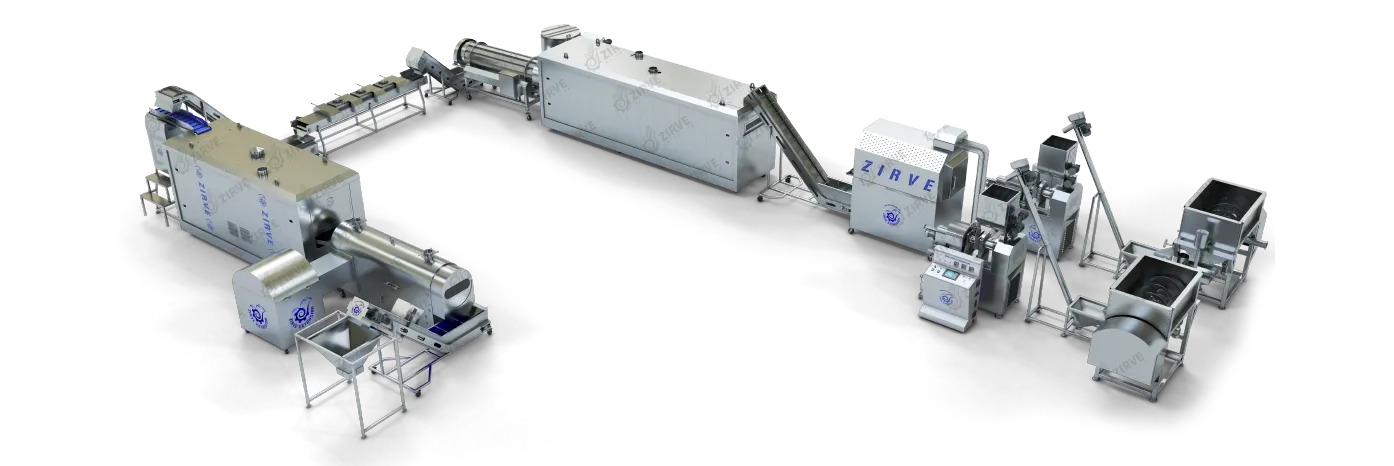

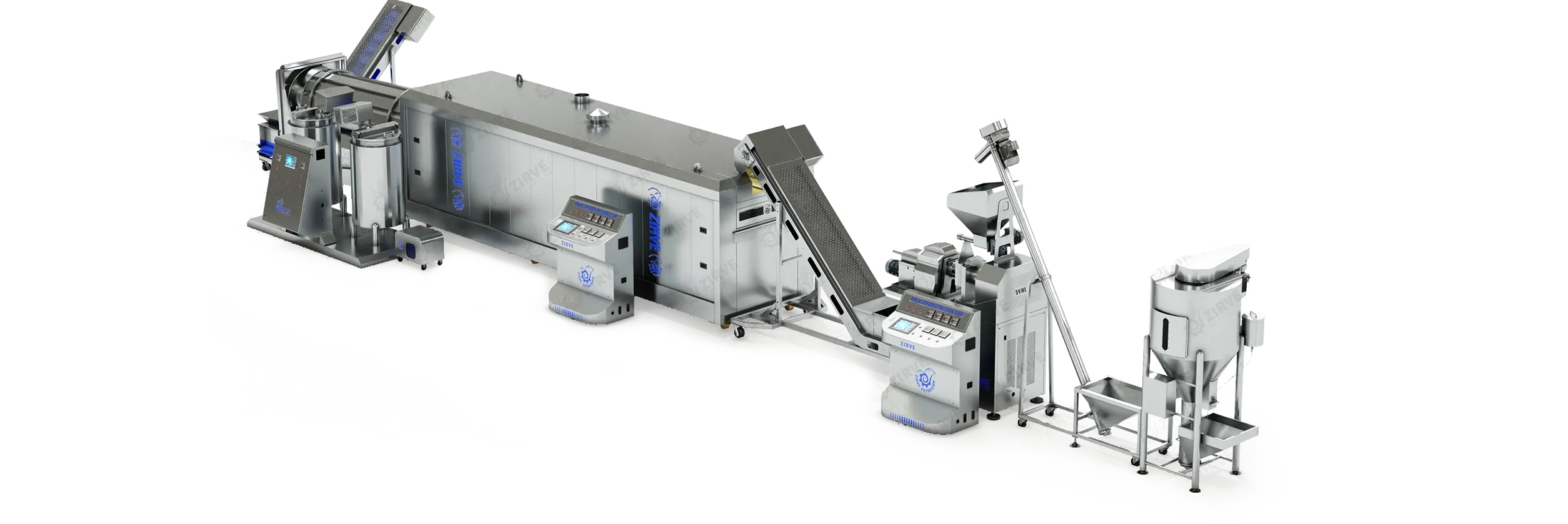

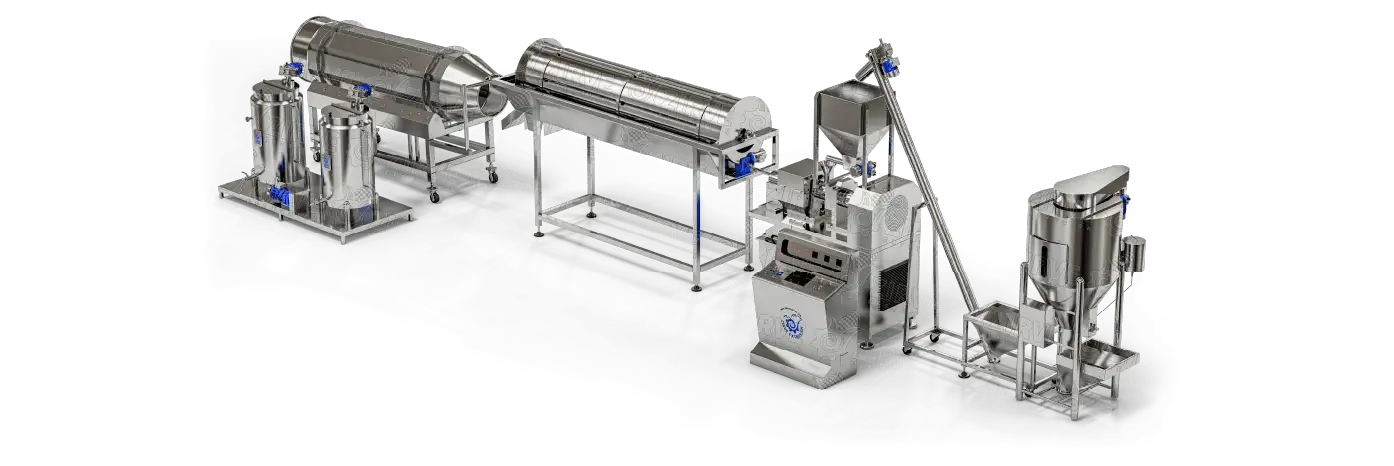

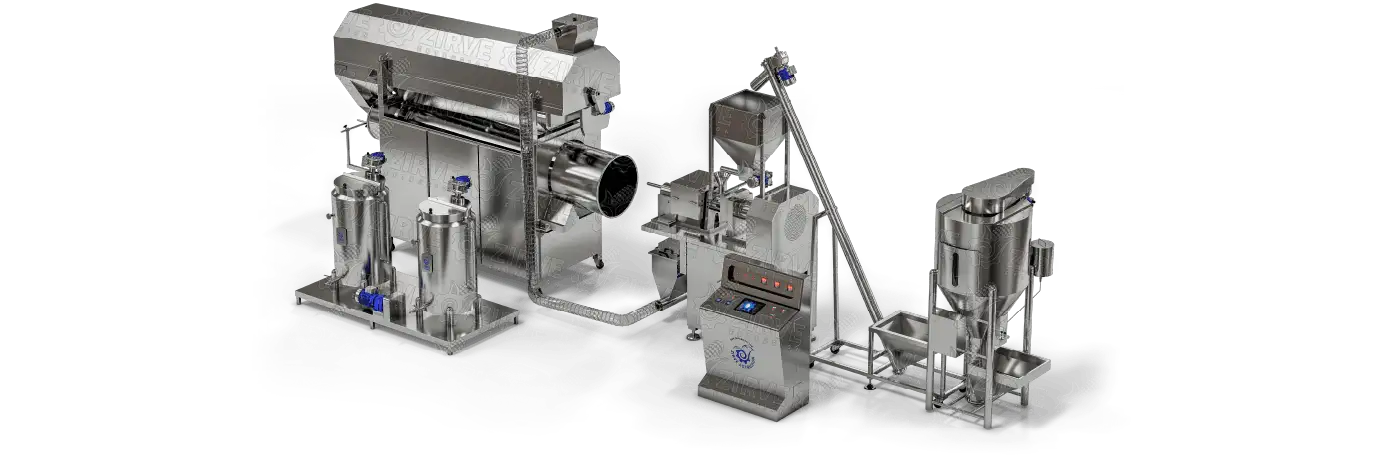

Function: blowing and forming the grain depending on the required shape. Model: AMERICAN EXTRUSION Production capacity is from / 175 / to / 200 / kg per hour The structure is made of thermally coated iron and covered with plates made of (Stainless Steel) thickness 2 mm (Bearings) from company SKF-SWEDEN ) (Inhibitor) from company (SKF-SWEDEN ) ( The Engine ) from company NERIMOTORI-ITALY /50/ Hp (Invertor) from company (LS-S KOREA to control the speed of the main engine Provided by material tank made of (Stainless Steel 304) With level control sensors It is equipped with a main helix to feed the material pressure helix controlled inverter from company (LS-S KOREA) All extruders are electronically controlled by 3 (inverters) from company (LS-S KOREA) The length of a piece of chips is controlled by an electronically variable speed knife (Invertor)from company (LS -S KOREA) . All extruder operations are controlled by a main control panel with a special hot venting system made of (Stainless Steel) with wheels for easy movement Multi-speed cutter to control the chips length with a (Korean - inverter LS) brand Equipped with a Turkish heater that control the temperature by a precise temperature clock from a company(AUTONICS-S KOREA) Helix feeders are made from the finest metals and processed with the latest thermal furnaces (vacuum furnace technology). The extruder is equipped with a cooling mechanism by water (closed circuit) American Extrusion ITALYAN Model Equipped with a cooling air set ITALYAN MODEL. separate control panel equipped with air vents and filters French (SCHNEIDER) brand and (Korean -LS- brand) with electronic and electrical protection. The control panel is tightly isolated for preventing dust from entering. The control panel is equipped with a 12-inch color touch screen (LS) with three languages on demand to fully control the mechanism of the line of chips. A detailed power scheme Attached with the control panel