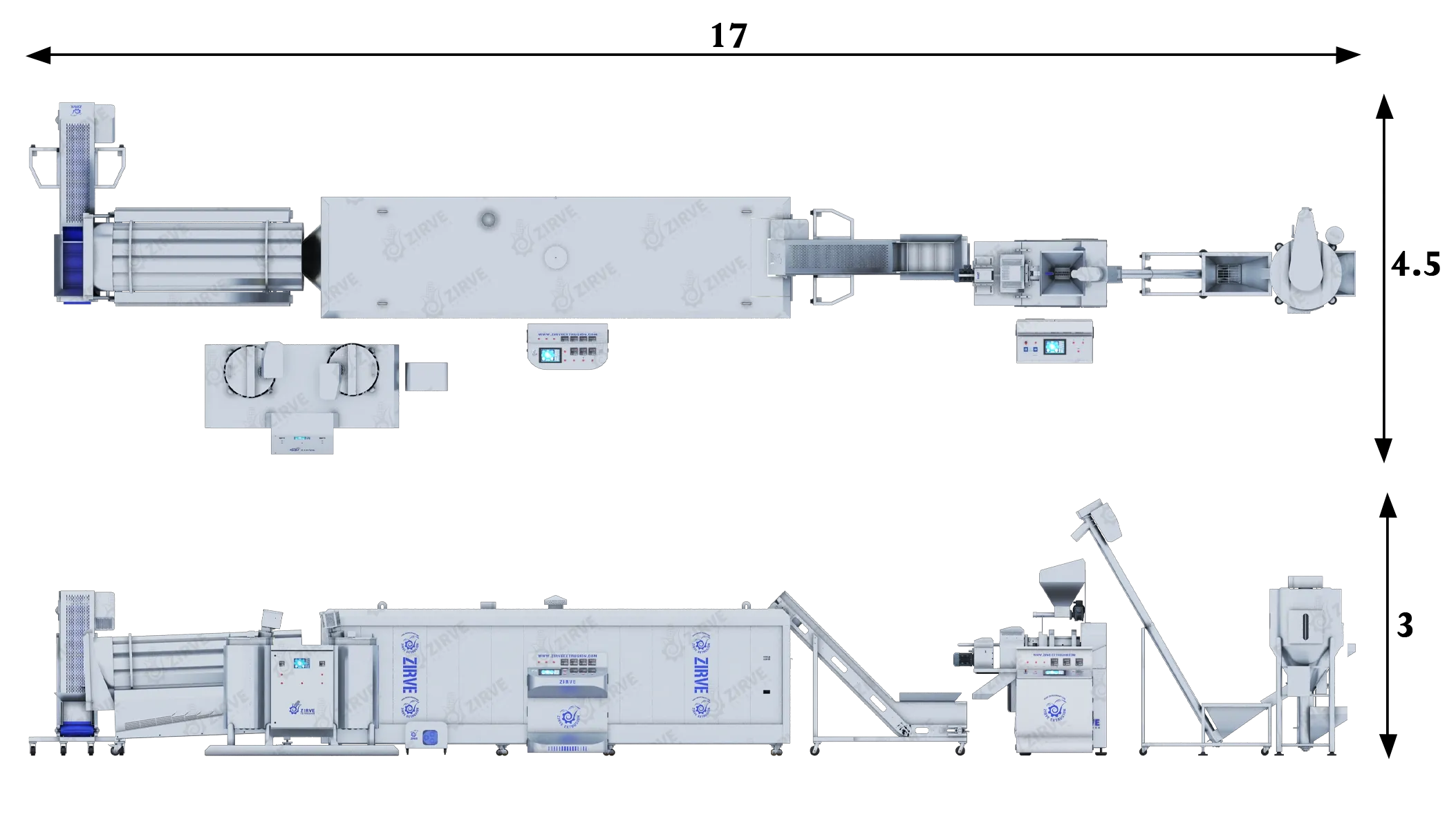

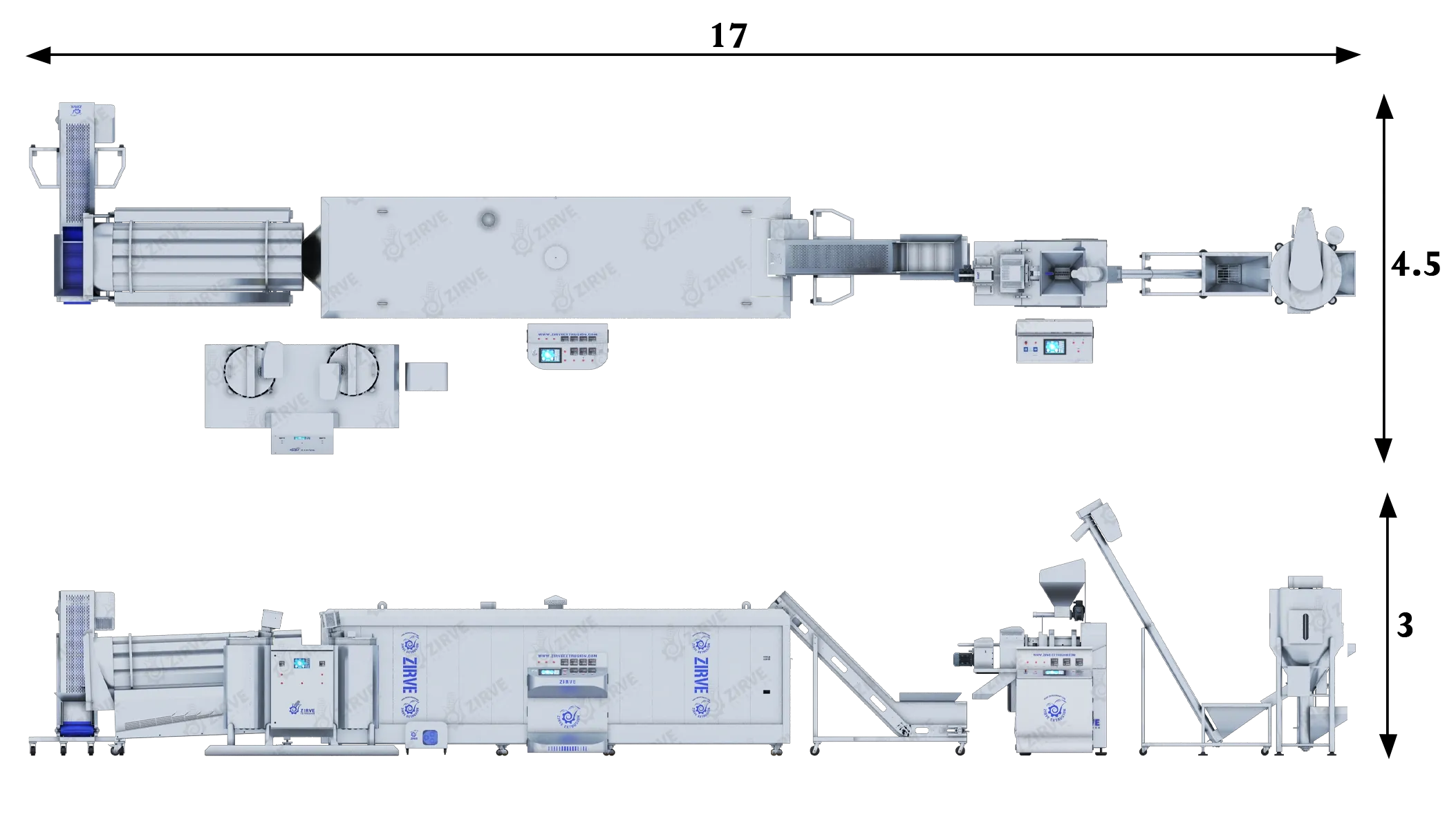

<p><strong>Function: roasting and drying the wet of chips corns completely, using hot air (American Extrusion System).</strong></p><p><strong> </strong></p><p><strong>Production capacity: /200/ - /500/ kg.</strong></p><p><strong> </strong></p><p><strong>It can operate on diesel or gas LPG or as required.</strong></p><p><strong> </strong></p><p><strong>Made of: (Stainless Steel 304)</strong></p><p><strong>( The Engine ) : (GAMAK- TURKEY)</strong></p><p><strong> (Gearbox) : )VARVEL-ITALY(</strong></p><p><strong>(Burner) : ( ECOFLAM - ITALY ) </strong></p><p><strong>(Electrical Parts) : (SCHNEIDER-FRANCE) (LS-S KOREA)</strong></p><p><strong> </strong></p><p><strong>Length: /6 / m Width:/1.5/ m</strong></p><p><strong>The width of the conveyor line carrying the pieces of chips is / 1 / m. It is equipped with the following:</strong></p><p> <strong>Automatic cleaning mechanism for the mesh bearing the pieces of chips .</strong></p><p><strong>(LS – KOREA) (inverter) to control the speed of the mesh bearing the pieces of chips.</strong></p><p> <strong>Automatic heat and programmable thermometers (quantity -2).</strong></p><p> <strong>Heating chamber that can be dismantled and installed for maintenance. </strong></p><p><strong>It is made of (Stainless Steel304) and designed to withstand temperatures up to / 800 / degrees.</strong></p>