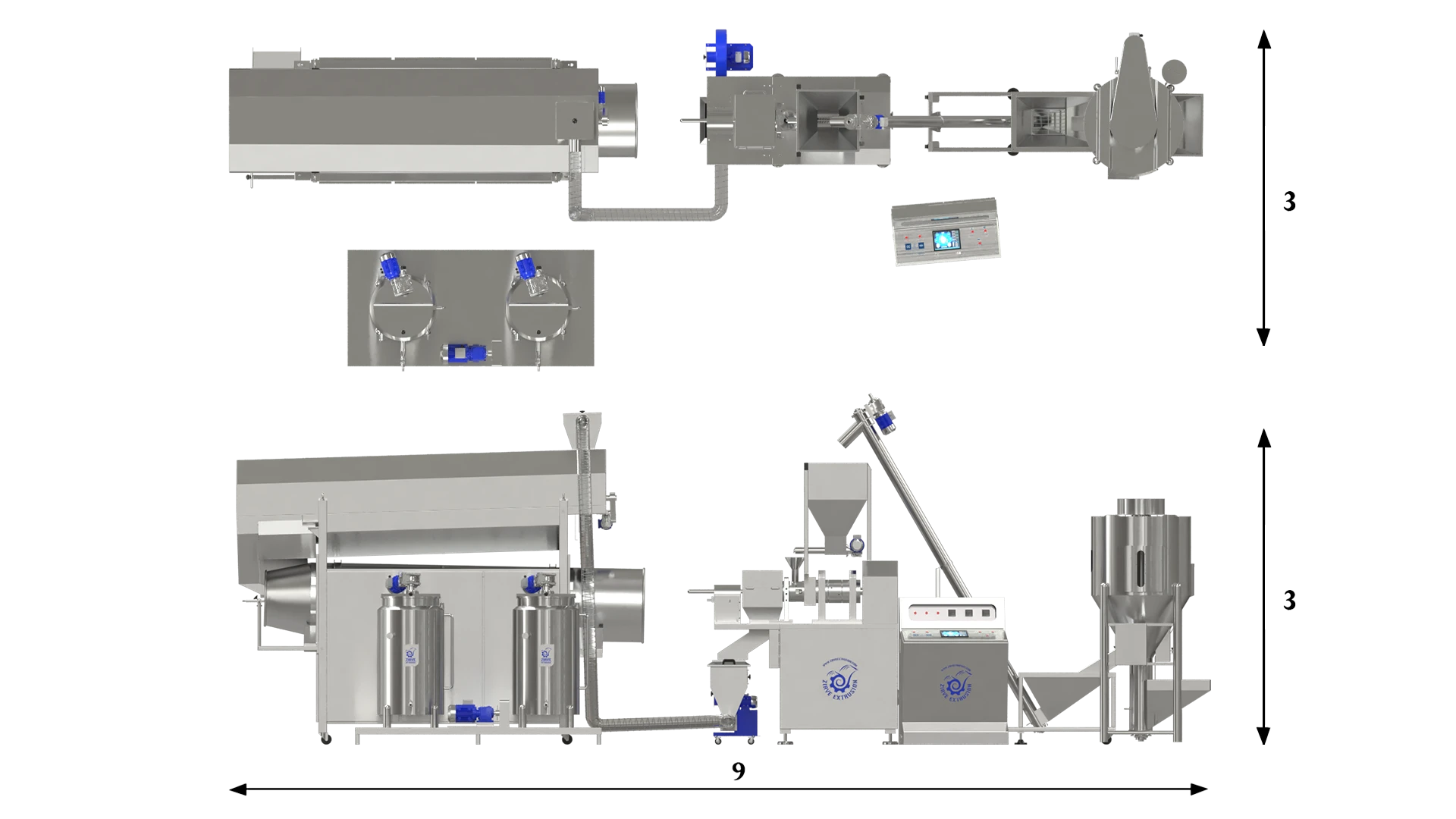

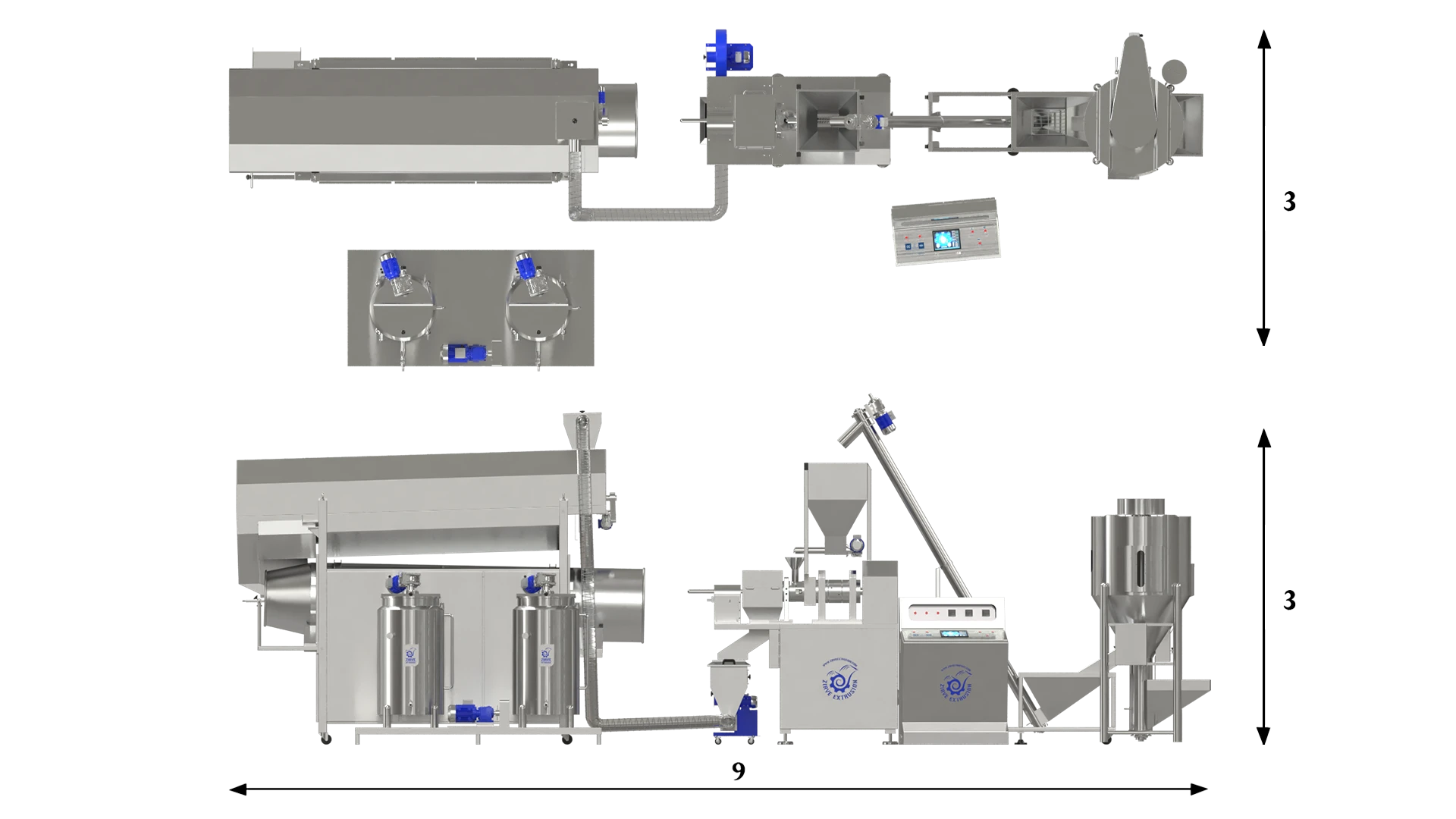

<p></p><p><strong>THE DRYER :</strong></p><p><strong>Function: Roasting and drying the chips .</strong></p><p><strong> The production capacity is (200) kg/h. </strong></p><p><strong>A cylinder made of / stainless steel 304 / </strong></p><p><strong>with a diameter of / 85 / cm</strong></p><p><strong> length of /400 / cm.</strong></p><p><strong> The drying is done by heat (heat source is gas or electric radiators as required). </strong></p><p><strong>The dryer is covered with two layers of stainless steel, with thermal insulator between them to reduce heat loss and save energy as much as possible. </strong></p><p><strong>Equipped with a mechanism to remove the impurities that may result from the dryer rotation and the product friction. A Turkish / 1 / HP motor brand YILMAZ.</strong></p><p><strong> An electrical panel with all necessary protection elements, all the parts are from French SCHNEIDER brand. </strong></p><p><strong>The speed of the dryer is electronically controlled (inverter).</strong></p><p></p><p><strong>SEASSONING DRUM:</strong></p><p><strong>Function: mixing the chips grains with flavor and oil </strong></p><p><strong>Length : / 3 /m </strong></p><p><strong>outer diameter / 85 /cm. </strong></p><p><strong>Made of (stainless steel 304)</strong></p><p><strong>(The Engine ) : from company (GAMAK- TURKEY) </strong></p><p><strong>(Gearbox) : from company (VARVEL-ITALY) </strong></p><p><strong>The seasoning speed is controlled electronically by an inverter / 1.5 / kW The process of the scales is designed so as to prevent the accumulation and the agglomeration of the flavor </strong></p><p><strong>It can automatically calibrate the sloping to control the time of the chips that passes inside. </strong></p><p><strong>It is equipped with the following: It is equipped with a flavor sprayer – an advanced American model which can be calibrated. a chrome cover by the exit side of the material; </strong></p><p><strong>it can be opened and closed for easy cleaning. a chrome cover by the exit side of the material; </strong></p><p><strong>it can be opened and closed for easy cleaning.</strong></p><p></p>