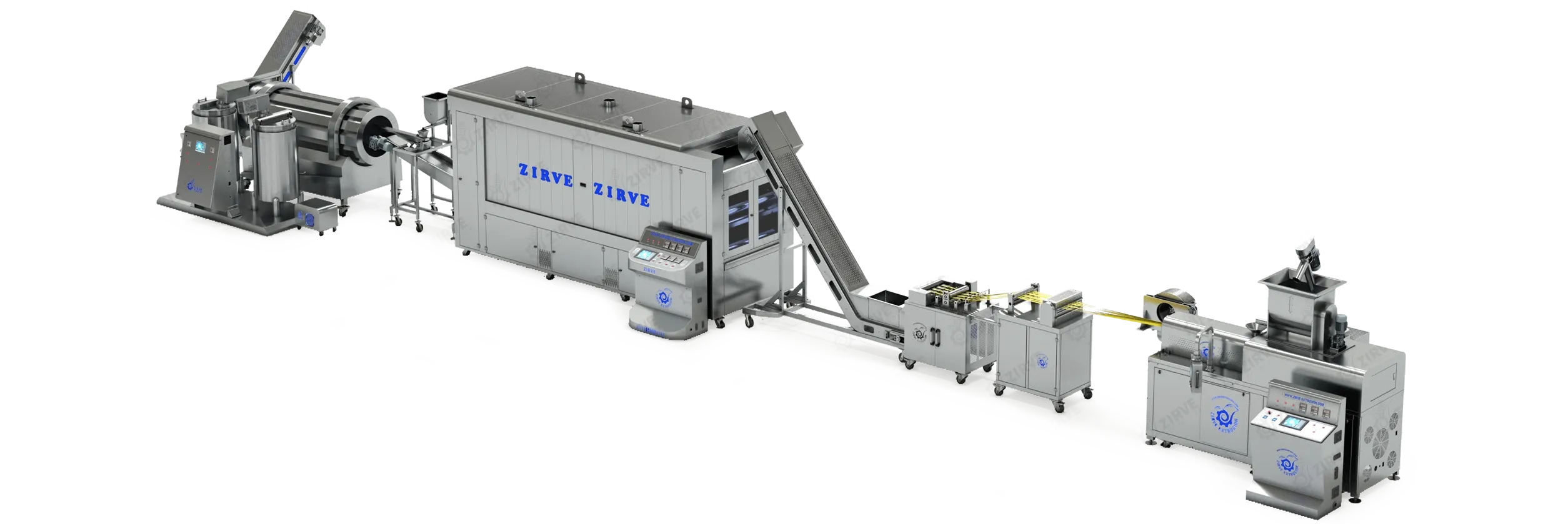

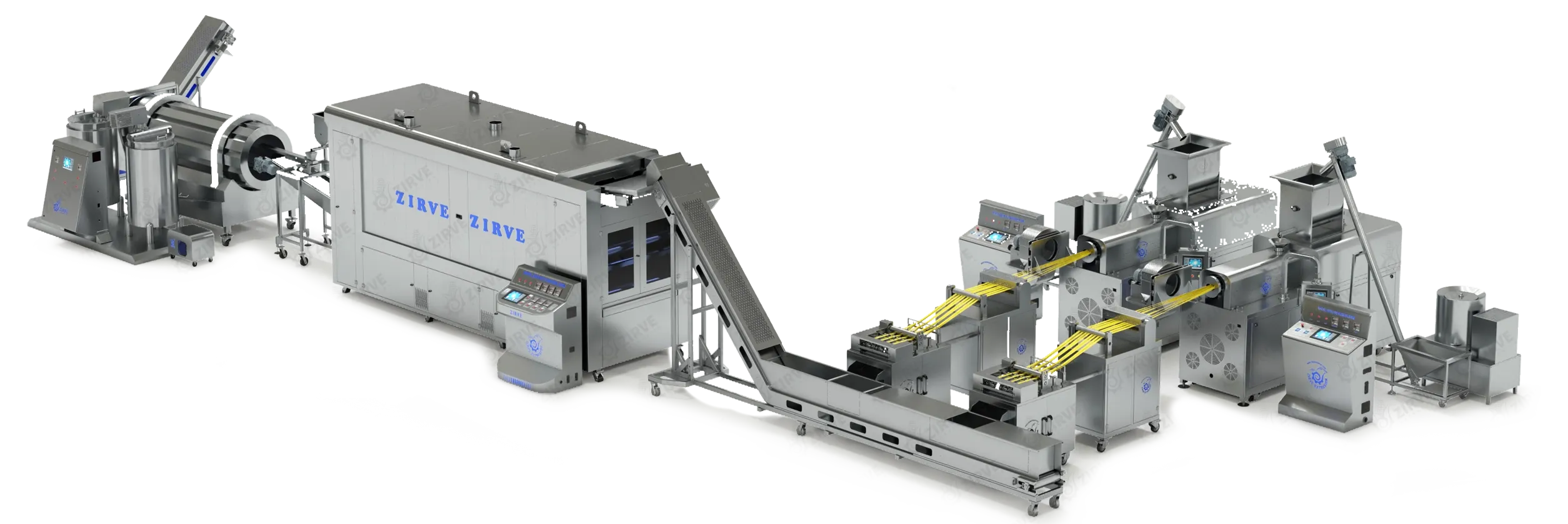

Double-screw extruder (helical) of French origin. Equipped to work with all types of flour and grits (corn flour, wheat flour, oat flour, etc.). The main motor is from Turkey, GAMAK, with a power of 50 horsepower and 900 revolutions per minute. Equipped with a Japanese-made gearbox capable of withstanding continuous 24/7 work pressures. The connection between the motor and the extruder is done through 6 couplings and shafts to protect the gearbox and screws from any errors. Equipped with an advanced and modern cooling system for the gearbox through a water circuit. Equipped with screws made from the finest metals and processed in the latest vacuum furnaces. Equipped with three heating stages with seven heaters to control the heating process of the screws, with the ability to control each group independently through three digital temperature controllers from AUTONICS (South Korea). Equipped with a main feeding tank with a mixing and stirring mechanism to maintain the homogeneity of the mixture before entering the extruder, with a capacity of 100 kg. Equipped with a feeding and feeding screw with a programmable mechanism to control the feed speed, with an Italian gearbox from Varvel (750 watts). Equipped with a French model quad or dual blade cutting device that is adjustable and calibrated smoothly and easily to produce various shapes of traditional puffed chips. The electrical panel is integrated with the structure, made of food-grade chrome 304 and equipped with three cooling and ventilation fans and filters. All breakers, switches, and thermal protections are from Schneider. The inverters for motor control and drive are from LS. Equipped with meters to monitor frequency, current, and hertz. The external structure of the extruder is clad with a layer of food-grade chrome 304 to maintain its appearance and facilitate cleaning.