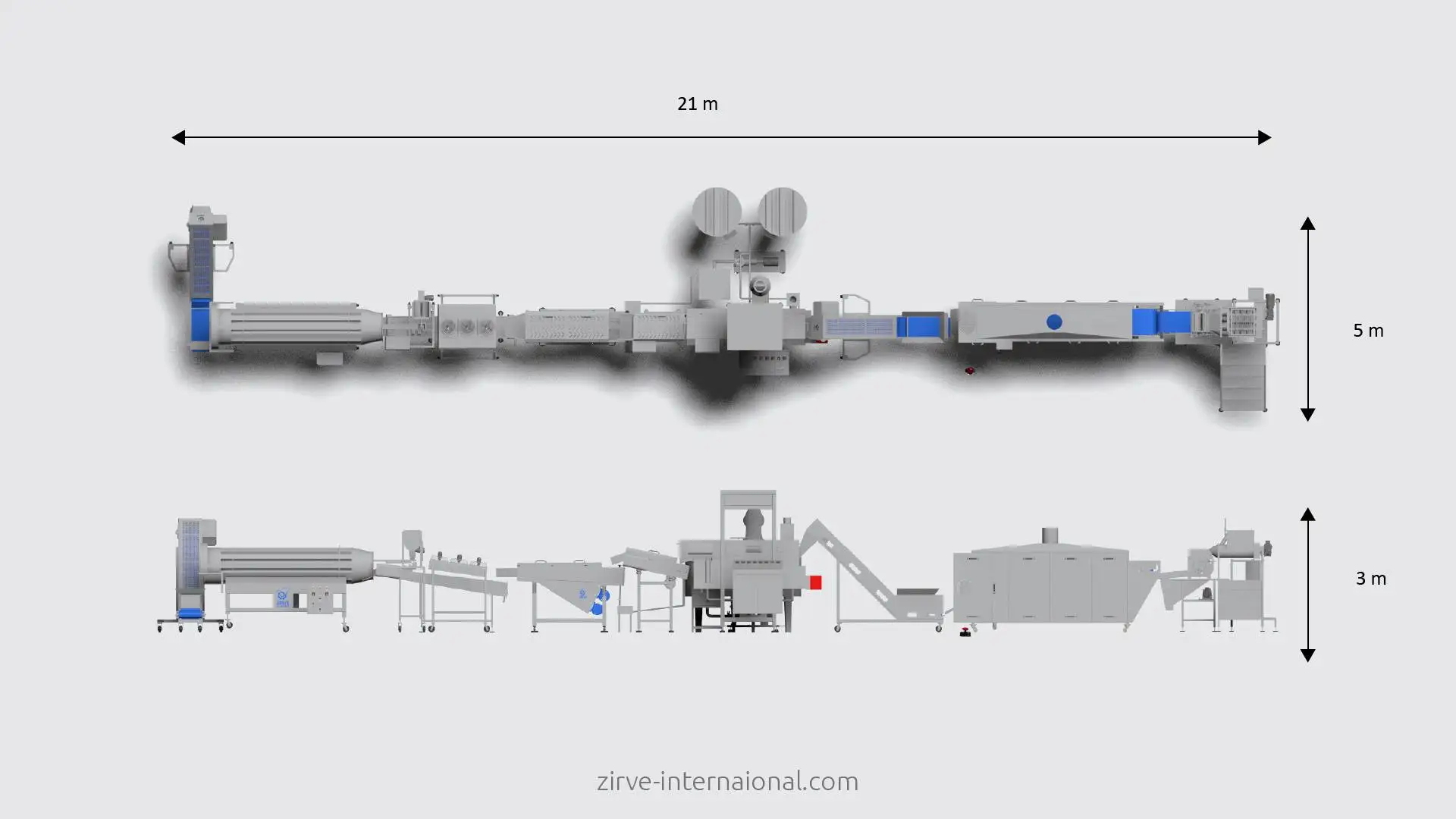

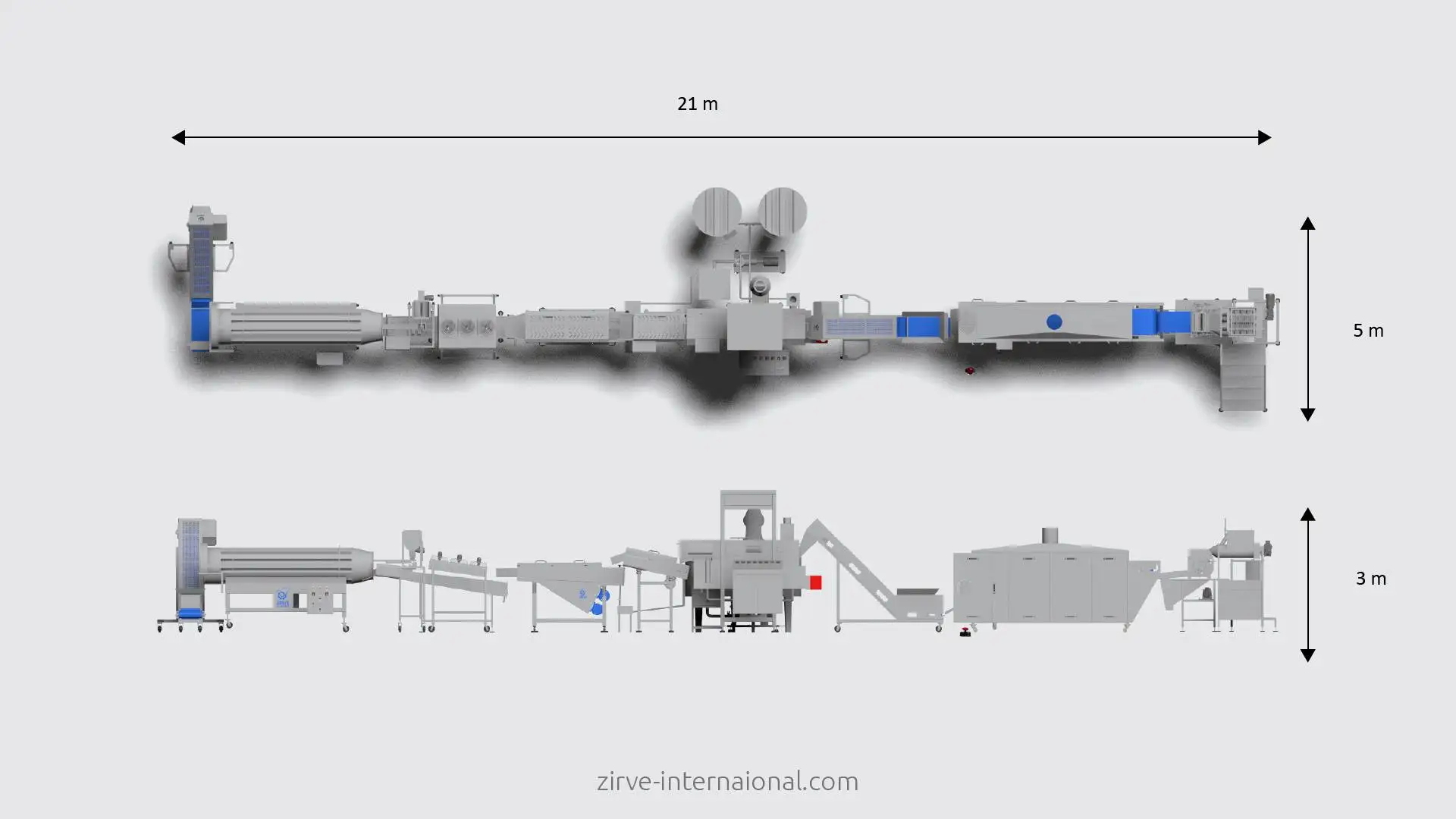

<p><strong><span style="color:rgb(55, 65, 81);">Function: High-precision engineering designer to receive tortilla pieces in their geometrically consistent shape at the moisture stage without moving them.</span></strong></p><p style="text-align:start"><strong><span style="color:rgb(55, 65, 81);">The first baking process, drying, and moisture removal take place in two stages on parallel conveyors. The tortilla pieces are flipped to the other end when moving to the second conveyor to reach the roasting and moisture removal process on the lower end of the tortilla. In the final stage (conveyor 3), cold air is blown from the top and bottom to cool the pieces before they move to the frying stage.</span></strong></p><p style="text-align:start"><strong><span style="color:rgb(55, 65, 81);">Number of oven stages: 3</span></strong></p><p style="text-align:start"><strong><span style="color:rgb(55, 65, 81);">Production capacity: 200 to 500 kg.</span></strong></p><p style="text-align:start"><strong><span style="color:rgb(55, 65, 81);">Runs on diesel or LPG gas as requested.</span></strong></p><p style="text-align:start"><strong><span style="color:rgb(55, 65, 81);">Material: Stainless Steel 304.</span></strong></p><p style="text-align:start"><strong><span style="color:rgb(55, 65, 81);">Engine: GAMAK - TURKEY.</span></strong></p><p style="text-align:start"><strong><span style="color:rgb(55, 65, 81);">Gearbox: VARVEL - ITALY.</span></strong></p><p style="text-align:start"><strong><span style="color:rgb(55, 65, 81);">Burner: ECOFLAM - ITALY.</span></strong></p><p style="text-align:start"><strong><span style="color:rgb(55, 65, 81);">Electrical Parts: SCHNEIDER - FRANCE and LS-S KOREA.</span></strong></p><p style="text-align:start"><strong><span style="color:rgb(55, 65, 81);">Oven length: 3 meters.</span></strong></p><p style="text-align:start"><strong><span style="color:rgb(55, 65, 81);">Oven width: 1.5 meters.</span></strong></p><p style="text-align:start"><strong><span style="color:rgb(55, 65, 81);">Conveyor belt width carrying tortilla pieces: 1 meter.</span></strong></p>